(This is the second of two posts looking at nine website metrics which can be used to achieve zero landfill waste and is based upon General Motors’ blueprint for achieving zero landfill waste. You can read part one here).

Strengthening Supplier Partnerships

All businesses large and small have suppliers, so you should look upstream to try and work co-operatively with your suppliers to eliminate waste. For example, useful discussions can be had around packaging, or suppliers may be interested in taking your waste for reuse in their own processes.

Ultimately, looking at the supplier partnerships and building a sustainability culture will bring the business’ strategic aim of achieving zero landfill waste into reality as employees and suppliers self-select depending upon their compatibility with the company’s long term goals.

Resolve Regulatory Challenges

Although sustainability and waste reduction may be high on your company agenda, the regulatory structure supporting them is nowhere near as developed or in depth as is it in many other aspects of business life, especially at the local level. It’s therefore a good idea to be proactive and seek out associations and groups who share the same objectives as you so that you can face any regulatory hurdles together.

Achieve Landfill Free

It may sound obvious, but once all of these steps are in place you can now start to move towards achieving zero landfill waste. It will not happen overnight, which is why having the metrics in place will help you to measure the effectiveness of various activities and adapt and improve them as necessary.

It’s also important that these metrics are published on the company’s website. This is not just to give a data-driven view of the success of your ambition but also to communicate it to other stakeholders: for example, detailing those associations you belong to as part of your zero waste drive can help to attract suppliers who are in tune with your long term goals.

Improve Efforts

Of course, achieving zero landfill waste is not the end of the story. If you’ve defined that as over 90% of waste going to landfill then there’s always room for improvement. However there’s always other areas which can be improved upon as well because as waste production falls so do costs and environmental impacts.

Remember: reduction should always come first before reuse and recycling, so until your enterprise really does produce zero waste (landfill or otherwise), there is always scope for improvements.

Share Best Practices

One of the most interesting things about the drive towards sustainability is that it has opened up the whole spectrum of best practice to all comers. Businesses which have a success in driving down their waste production should be prepared to stand up and speak about their experiences, offering them as best practice and being willing to see them improved in a stepwise manner by other companies.

Similarly a company should not feel bashful about joining in the debate with other businesses and helping to improve their best practices. This is why talking to suppliers and participating in associations with non-financial objectives are key to attaining business sustainability.

Ultimately its all about communication and co-operation, which is why the publication of metrics on corporate websites is such a critical factor.

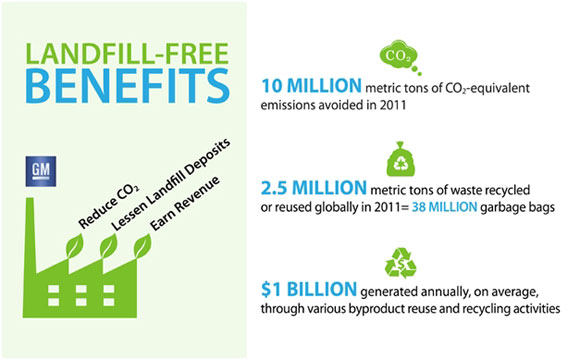

Image © General Motors.

Lucy is Editor at Corporate Eye